The Untapped Potential of 3,3-Dimethylacrylic Acid Methyl Ester in Bio-Based UV-Curable Coatings

3,3-Dimethylacrylic Acid Methyl Ester is gaining traction in bio-based UV-curable coatings due to its fast curing, sustainability, and performance benefits.

NEWARK, DE, UNITED STATES, June 5, 2025 /EINPresswire.com/ -- The global specialty chemicals industry is in the midst of a structural shift, driven by sustainability mandates, technological advancements, and changing customer expectations. Among a host of chemical compounds contributing to this transformation, 3,3-Dimethylacrylic Acid Methyl Ester remains one of the lesser-known, yet highly promising materials. This compound, often overshadowed by its mainstream counterparts like methyl methacrylate and ethyl acrylate, is gaining attention for its potential applications in bio-based UV-curable coatings. Despite its niche market share today, the compound is poised to make significant contributions to environmentally friendly materials innovation—especially within the coatings and resin intermediates segment.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-15077

𝐔𝐧𝐝𝐞𝐫𝐬𝐭𝐚𝐧𝐝𝐢𝐧𝐠 𝟑,𝟑-𝐃𝐢𝐦𝐞𝐭𝐡𝐲𝐥𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐀𝐜𝐢𝐝 𝐌𝐞𝐭𝐡𝐲𝐥 𝐄𝐬𝐭𝐞𝐫 𝐚𝐧𝐝 𝐌𝐚𝐫𝐤𝐞𝐭 𝐏𝐨𝐬𝐢𝐭𝐢𝐨𝐧𝐢𝐧𝐠

3,3-Dimethylacrylic Acid Methyl Ester, chemically known as methyl methacrylate isomer, is primarily used as an intermediate in the synthesis of performance-enhancing polymers. It features unique steric and electronic properties due to its branched molecular structure, making it an ideal candidate for formulating specialty acrylates. The global market for this compound is relatively small but is expected to witness robust growth as demand rises for precision-engineered, functional esters in high-performance applications.

Recent market estimates suggest that while the broader acrylate ester market is expanding at a CAGR of around 5–6%, niche compounds like 3,3-Dimethylacrylic Acid Methyl Ester could experience double-digit growth, particularly within the UV-curable coatings domain. Despite limited mainstream visibility, queries around specialty acrylates, UV-curable resin intermediates, and green monomer technologies have been steadily increasing, indicating growing interest from industry insiders.

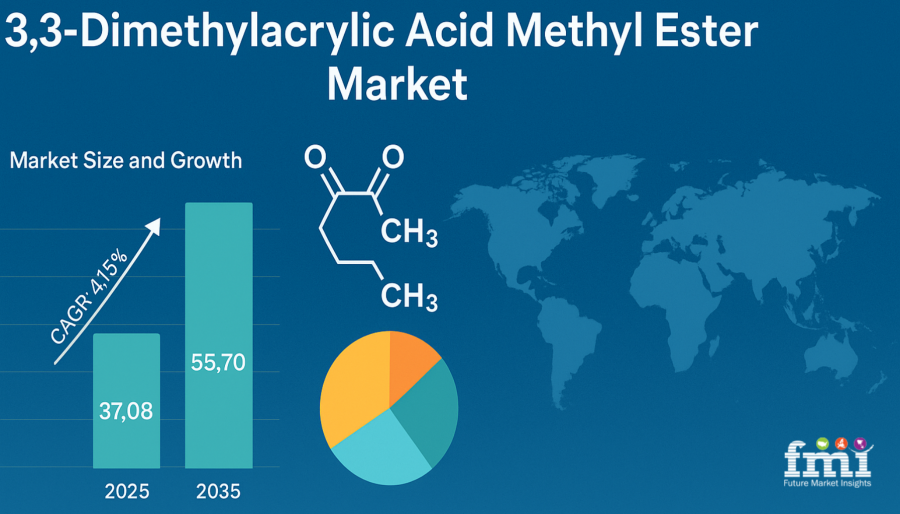

According to Future Market Insights, the global 3,3-Dimethylacrylic Acid Methyl Ester market is projected to grow steadily from USD 37.08 million in 2025 to USD 55.70 million by 2035, reflecting a CAGR of 4.15%.

𝐓𝐡𝐞 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐒𝐡𝐢𝐟𝐭: 𝐑𝐨𝐥𝐞 𝐢𝐧 𝐁𝐢𝐨-𝐁𝐚𝐬𝐞𝐝 𝐔𝐕-𝐂𝐮𝐫𝐚𝐛𝐥𝐞 𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬

The coatings industry has long relied on solvent-borne systems that release volatile organic compounds (VOCs) and other environmentally hazardous substances. In contrast, UV-curable coatings offer a low-emission, energy-efficient alternative. Within this sub-sector, bio-based UV-curable materials are garnering interest for their reduced environmental footprint and improved occupational safety.

3,3-Dimethylacrylic Acid Methyl Ester stands out in this context due to its compatibility with bio-renewable feedstocks and its ability to undergo photopolymerization with minimal energy input. Its molecular configuration allows it to react rapidly under UV light, forming robust and highly crosslinked polymer matrices. This makes it a valuable candidate for applications in wood finishes, automotive topcoats, and even 3D printing resins—where rapid curing and durability are non-negotiable performance criteria.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/3-3-dimethylacrylic-acid-methyl-ester-market

𝐂𝐨𝐦𝐩𝐚𝐫𝐚𝐭𝐢𝐯𝐞 𝐀𝐝𝐯𝐚𝐧𝐭𝐚𝐠𝐞𝐬 𝐎𝐯𝐞𝐫 𝐂𝐨𝐧𝐯𝐞𝐧𝐭𝐢𝐨𝐧𝐚𝐥 𝐀𝐜𝐫𝐲𝐥𝐚𝐭𝐞𝐬

What differentiates 3,3-Dimethylacrylic Acid Methyl Ester from more conventional acrylates is its tertiary carbon structure. This gives it better resistance to hydrolysis and oxidation, crucial for maintaining coating integrity in harsh environmental conditions. Moreover, it exhibits lower viscosity compared to methyl methacrylate, making it easier to incorporate into high-solids formulations without compromising processing ease.

In terms of polymerization kinetics, the compound shows faster cure rates, enabling manufacturers to reduce curing times while maintaining high throughput. For UV-curable systems, this translates to higher efficiency in industrial lines, with fewer energy inputs and reduced cycle times. These attributes are especially important for sectors like electronics and medical devices, where precise and reliable coating properties are essential.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐇𝐢𝐧𝐝𝐞𝐫𝐢𝐧𝐠 𝐌𝐚𝐢𝐧𝐬𝐭𝐫𝐞𝐚𝐦 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Despite its technical advantages, the commercial adoption of 3,3-Dimethylacrylic Acid Methyl Ester faces several roadblocks. First is the issue of scale. The compound is currently produced in relatively low volumes, making it less economically viable for price-sensitive markets. Additionally, the limited number of suppliers means that procurement reliability is often a concern for buyers looking for secure, long-term sourcing.

From a regulatory standpoint, while the compound is generally regarded as safe for industrial use, its classification in certain jurisdictions may require additional approvals or reformulation compliance, especially in consumer-facing applications. Lastly, the lack of awareness and technical expertise in working with this ester limits its broader uptake among formulation chemists and product development teams.

𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐃𝐫𝐢𝐯𝐞𝐫𝐬: 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐚𝐧𝐝 𝐂𝐚𝐬𝐞 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬

Innovation in the field of acrylate esters is gradually changing this landscape. For instance, a European university recently published a study highlighting the superior performance of 3,3-Dimethylacrylic Acid Methyl Ester in anti-scratch and heat-resistant coatings. Meanwhile, a startup in the Asia-Pacific region has incorporated this compound in a prototype line of plant-based 3D printing resins, aiming to commercialize products that offer faster curing and superior structural strength.

𝐇𝐲𝐝𝐫𝐨𝐜𝐚𝐫𝐛𝐨𝐧𝐬, 𝐏𝐞𝐭𝐫𝐨𝐜𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬, 𝐚𝐧𝐝 𝐎𝐫𝐠𝐚𝐧𝐢𝐜 𝐂𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬: https://www.futuremarketinsights.com/industry-analysis/hydrocarbons-petrochemicals-and-organic-chemicals

These use cases highlight the compound's versatility and potential beyond conventional coating applications. Its incorporation into R&D pipelines across industries like electronics, optics, and even biomedicine further expands its opportunity space. As demand grows for functional, green materials that don’t sacrifice performance, these case studies may serve as early indicators of a broader market shift.

𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤 𝐚𝐧𝐝 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐑𝐞𝐜𝐨𝐦𝐦𝐞𝐧𝐝𝐚𝐭𝐢𝐨𝐧𝐬

Looking ahead, the market for 3,3-Dimethylacrylic Acid Methyl Ester is expected to witness meaningful growth, particularly as regulatory and environmental pressures reshape the materials landscape. Companies that invest early in sourcing strategies, application R&D, and customer education are likely to benefit from a first-mover advantage. Integrating this compound into value-added products like UV-curable adhesives, specialty sealants, and sustainable coatings could open up high-margin opportunities, especially in regions with strong green chemistry mandates such as the EU and Japan.

𝐓𝐨𝐩 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐬 𝐒𝐭𝐮𝐝𝐢𝐞𝐝 𝐢𝐧 𝐭𝐡𝐞 𝟑,𝟑-𝐃𝐢𝐦𝐞𝐭𝐡𝐲𝐥𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐀𝐜𝐢𝐝 𝐌𝐞𝐭𝐡𝐲𝐥 𝐄𝐬𝐭𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭

By Purity:

Based on purity, the industry is classified as < 98% and > 98%.

By Application:

By application, the industry is divided into pharmaceuticals, chemical reagent, flavoring agent and others.

By Region:

By region industry is classified into North America, Latin America, Europe, Asia Pacific, and the Middle East & Africa.

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Europe Advanced Aerospace Coatings Market: https://www.futuremarketinsights.com/reports/europe-advanced-aerospace-coatings-market

Diketene Derivatives Market: https://www.futuremarketinsights.com/reports/diketene-derivatives-market

Neopentyl Glycol (NPG) Market: https://www.futuremarketinsights.com/reports/neopentyl-glycol-market

U.S. Non-Commercial Acrylic Paints Market: https://www.futuremarketinsights.com/reports/us-non-commercial-acrylic-paints-market

Low-Dosage Hydrate Inhibitors Market: https://www.futuremarketinsights.com/reports/low-dosage-hydrate-inhibitors-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Business & Economy

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release